Tour behind the scenes at our British weaving mills

Visiting the traditional UK weaving mills where The British Blanket Company's wool blankets are made is always a fun and fascinating experience. In today’s blog, Bethan and Joe invite you along for a behind the scenes tour! All our throws, scarves and picnic rugs are made in Britain and Ireland. On this most recent trip, we visited our mill in Yorkshire and another on the Yorkshire-Lancashire border.

It makes such a difference when you buy British - by supporting British heritage brands like ours, you help this historic industry to continue to thrive. Come along with us and we’ll tell you what it’s like to step inside a centuries-old woollen mill and guide you through the weaving process, from the arrival of the raw fleece to the finished wool blanket.

We arrived at the mill bright and early on a crisp winter morning. As with many Victorian mills, this one is next to a canal. In the past, horse-drawn barges were used to bring raw wool into the mills and transport the finished cloth out. British wool cloth was considered the finest quality all over the world.

Upstairs is the old yarn store where wool remnants are kept. Although the spools have been tossed together randomly, some inspiring accidental colour combinations have come about!

We love wool! Wool is the perfect material for weaving blankets. It's sustainable, soft, warm and looks beautiful in contemporary homes.

Where are The British Blanket Company’s wool blankets and scarves made?

All our wool blankets are scarves are made in the UK and Ireland, something we are really proud of! On today’s virtual tour, you’ll see inside two of our mills – one in Yorkshire, and one located right on the Yorkshire-Lancashire border.

Although the machinery used has been modernised over the years, the processes used in weaving a blanket are largely unchanged for centuries. This is a warping creel, which guides the yarns onto the warping beam in exactly the right order, without any tangles!

Bethan looks on as the warp threads go into the beam. Just one wool blanket can contain 1,300 warp threads.

We're always excited by the colours we can achieve by using wool. From subtle neutral shades, to zingy brights, wool is such a versatile material for weaving eye-catching blankets.

What’s the history and heritage of The British Blanket Company’s weaving mills?

Both the mills we visited date back to the Victorian era and have been weaving the finest wool cloth for generations. The last of their kind, these are the mills that have survived through challenging times over the years and continue to thrive today. Although the looms and spinning machines are faster, the weaving process and skills are almost unchanged since the mills were first built. It’s amazing to see how many processes are still done by hand, from threading the looms, to knotting the warp. History and heritage are woven into every strand!

What’s it like to go inside a traditional woollen mill?

The first thing you notice is the noise and the vibration of the looms. The whole building seems alive with throbbing energy that remains in your bones for a while after you leave… it’s an extraordinary experience!

The looms clatter very loudly, so you need to wear ear protection as you walk around. In the eighteenth and nineteenth centuries the female mill workers developed their own form of speech called “mee-mawing”, which was a cross between lip-reading and mime, so they could communicate over the noise of the looms. Each mill had its own dialect! Of course, everything is safer today and the modern electric looms are more efficient, but the pulsating sound of the mill is still striking.

There’s also a lovely warm scent of wool throughout the mill that comes from the lanolin in the wool and the warm water and steam used in the scouring process.

This wonderful spinning machine is where the fleece is turned into strong twisted yarn, ready to be woven into beautiful blankets.

What are the steps in making a woven wool blanket?

It’s hard to believe how many processes go into making just one woven wool blanket…

- Raw wool – arrives at the mill from New Zealand and South Africa, where the sheep produce the softest fleece for making blankets. From here, every single process happens in the UK.

- Dying – the fleece is dyed vibrant colours in huge metal vats of hot water.

- Blending – different colours of dyed fleece are blended together, like mixing paint. These yarns are called ‘melange’ and have a more subtle appearance than solid-dyed yarns.

- Carding – the fibres are combed on tiny metal pins to align them all in the same direction, ready for spinning.

- Spinning – the wool fibres are twisted together to create a strong, fine yarn.

- Warping – yarns are rolled onto a huge metal beam to create a warp. One of our blankets can have as many as 1,300 warp threads which have to be carefully aligned by a skilled warper to avoid tangles.

- Knotting – knotting one of the most skilled jobs in the mill. Each of the 1,300 warp threads is knotted to the next by hand!

- Weaving – finally onto the loom where the magic happens! The weft threads are fed through the warp threads by shuttles moving at lightning speed. The warp threads are individually lifted and lowered in a set order, which creates the pattern.

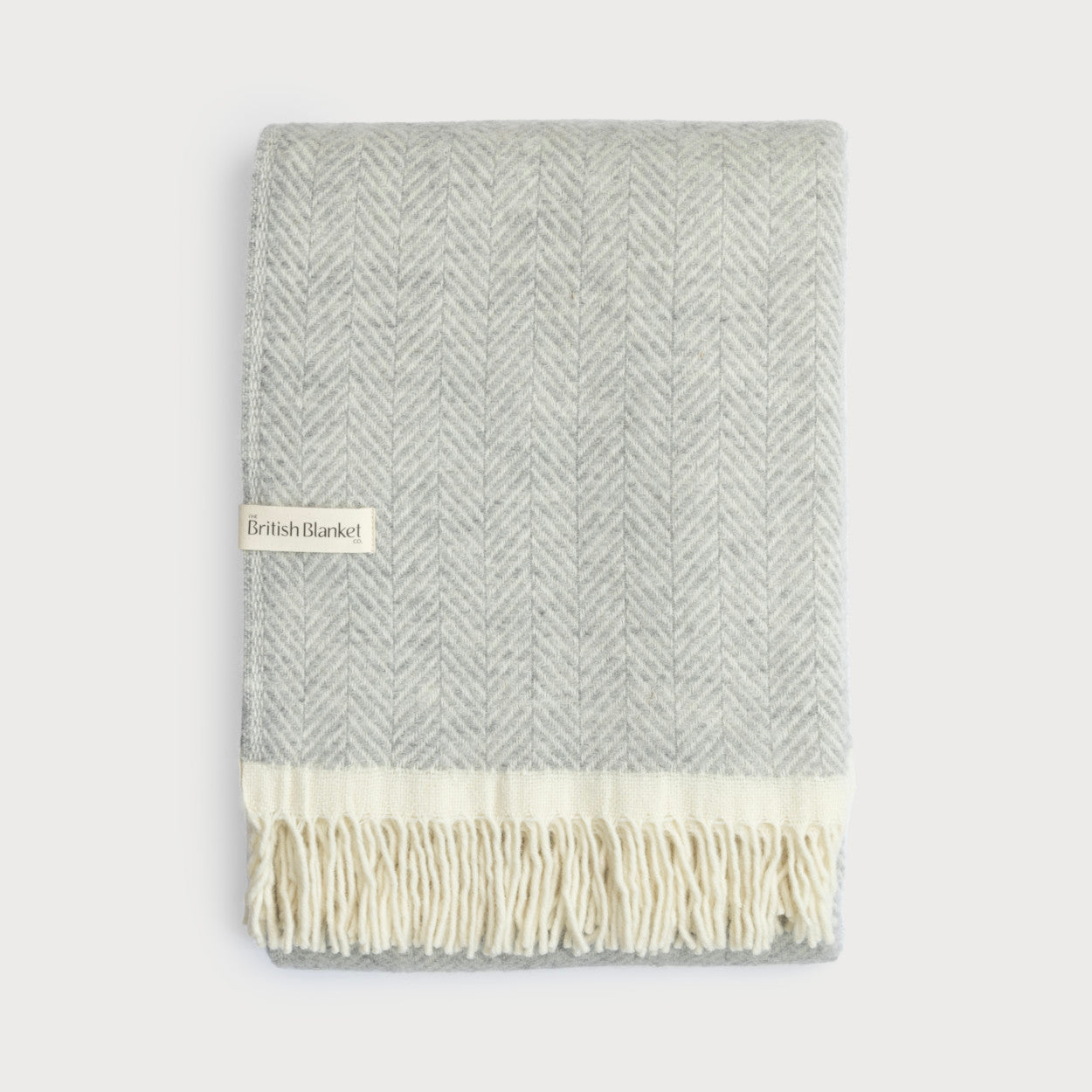

- Fringing – this is where the warp threads between each blanket are twisted into tassels.

- Inspection – every inch of cloth is inspected by eye and touch. Any loose threads or knots are invisibly mended by hand.

- Raising – the cloth is brushed with rollers covered in tiny pins, giving the fabric a softer and fluffier feel.

- Scouring – the cloth is washed in spring water and soap which slightly felts the fibres together, strengthening the cloth. It’s then carefully dried to reach its finished size.

- Cutting, labelling and folding – the tassels are cut by hand and a finished blanket is created!

Inside the weaving shed, everything seems to pulsate with the vibration and sound of the looms. This is where the magic really happens!

Every inch of cloth is checked over, by eye and by touch. This room has a lovely calm atmosphere compared to the clatter of the rest of the mill, with everyone deeply engrossed in their work.

Why are products made in Britain important in preserving heritage crafts?

Most of the skills that go into making a woven wool blanket remain unchanged from the eighteenth century, when the power loom was first invented. As mills have closed over the years, mostly due to competition from abroad, weaving skills that were once commonplace are in danger of decline. When you buy products made in Britain from a heritage brands like The British Blanket Company, you help support these historic mills and preserve traditional skills. If we can keep the mills thriving, the next generation will see weaving as a valid career path once again, and we can train apprentices to learn and preserve heritage crafts.

Have you seen our video? The British Blanket Company’s co-founders Bethan and Joe show you inside a historic weaving mill, explain more about our family business and the history of blanket weaving in Britain. It’s a fascinating and beautiful film that’s well worth a watch!

All photographs and video in this post are © The Blanket Shop Ltd 2022 and may not be copied or reproduced without permission.