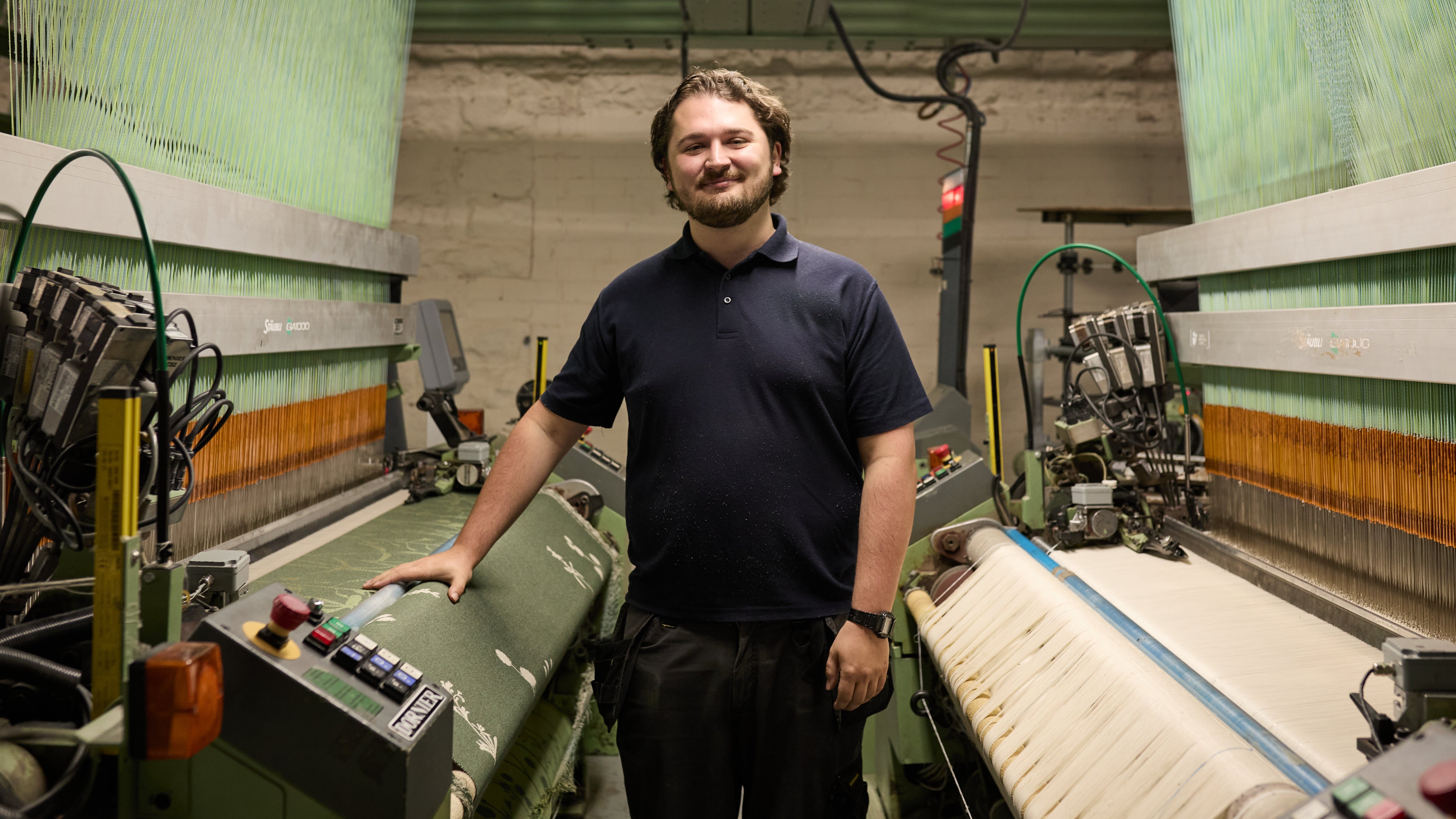

Our new Cloud Cotton blanket designs began life in Bristol and were woven for us in Lancashire, at a weaving mill with more than 150 years of history. In fact, Burnley once had more looms than there were people! It is a place where textile skills have been passed down through generations, and where traditional looms still clatter away alongside a modern approach to design and sustainability.

In today's blog, we'll head behind the scenes in the mill where our Cloud Cotton blankets are made, learn more about recycled cotton blankets, and gain an insight into the craft of cotton jacquard weaving.

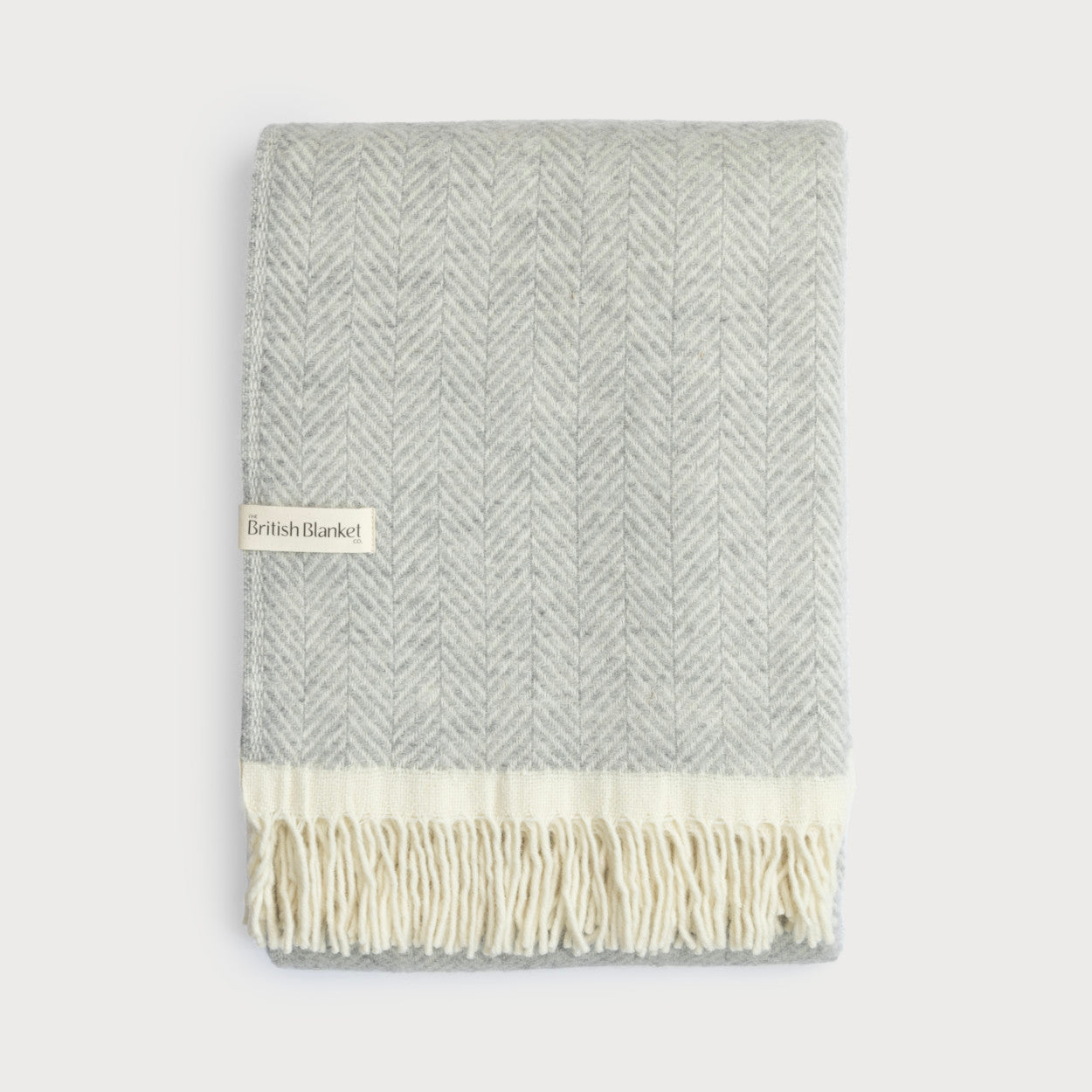

The British Blanket Company proudly makes all its blankets in the UK and Ireland, supporting local jobs and preserving traditional crafts. The Cloud Cotton blanket range is woven in Lancashire

Lancashire’s textile heritage

Lancashire was once known as the textile capital of the world. Many mills have since fallen silent, but a small number remain, keeping this important craft alive. Our mill is one of them. It has adapted with the times but never lost sight of the values of quality and care that have always defined British weaving.

From design to loom

Working with recycled cotton is no easy task. The fibres are shorter than virgin cotton, which makes them more challenging to weave. That is where the skill of the Lancashire weavers comes in.

For Cloud Cotton, the designs are brought to life on jacquard looms, which make it possible to create complex reversible patterns and curved lines. This technical ability allows our designs to flow across the cloth in a way that feels organic and balanced.

Unlike dobby looms that can only weave straight lines, jacquard looms can create woven patterns with curves, allowing us to design blankets with sweeping shapes and a fully reversible structure

Unlike dobby looms that can only weave straight lines, jacquard looms can create woven patterns with curves, allowing us to design blankets with sweeping shapes and a fully reversible structure

How a Cloud Cotton blanket is made

-

Collecting fabric waste

Our journey starts by gathering post-production cotton offcuts, the surplus fabric left behind from garment manufacturing and pattern-cutting. -

Sorting and preparation

The fabric is carefully sorted by recycling experts. Any non-cotton elements, such as zips or buttons, are removed, and the pieces are organised by colour, ready for transformation. -

Breaking down the fibres

Using specialist equipment, the cotton is broken back down into raw fibres. This step is crucial to ensure a high-quality base for spinning. -

Spinning new yarn

Once transformed, the fibres are spun into fresh yarns, each carrying the character of the recycled textiles it came from. No additional dye is needed as the colours are retained from the original fabrics. -

Weaving on jacquard looms

The new yarns are woven into cloth on jacquard looms, which allow us to create reversible patterns and soft, flowing lines. This is the moment our designs come to life. -

Finishing by hand

Each blanket is raised, brushed and inspected before being finished with a neat blanket-stitch border. This sewn edge strengthens the fabric and adds a traditional touch.

Each stage of the weaving and finishing process is overseen by skilled artisans, who are experts in their craft. Combining a contemporary design aesthetic with traditional craftsmanship is central to The British Blanket Company's mission

Sustainability at the heart

The Cloud Cotton collection gives new life to material that might otherwise have been wasted. With no extra dyes required and every fibre put to use, the process helps reduce textile waste and limit the demand for virgin resources. It is a way of weaving that takes modern environmental responsibilities seriously, while also celebrating the centuries-old skill of British makers.

Recycled cotton uses up to 80% water than virgin cotton because it doesn't require cultivation and dying. Virgin cotton production is very water-intensive, with one kilogram of cloth requiring up to 10,000 litres of water, while recycling cotton repurposes existing materials, reducing the need for new crops, land, and pesticides.

The British Blanket Company makes soft and beautiful blankets from recycled wool and recycled cotton.

Recycled cotton is a sustainable alternative to virgin cotton blankets as the re-use existing materials and use less water and energy to manufacture. Our Cloud Cotton blankets are brushed for an extremely soft and lofty finish, that feels as fluffy and thick as fleece, but is natural

The people behind the process

Behind every blanket are the craftspeople whose knowledge makes all the difference. From setting up the looms to checking each piece as it comes off the line and sewing the blanket-stitch border, their attention to detail is what turns recycled yarn into something soft, balanced and enduring. Their pride in the work is evident in every stitch thread.

When you bring a Cloud Cotton blanket into your home, you are welcoming a piece that has been made with care for the heritage of weaving and the environment. These blankets reflect everything we stand for at The British Blanket Company: thoughtful design, authentic craftsmanship and natural materials, made to be part of your life for years to come.